JS-12A Automatic Quantitative Powder & Granule Filling & Packaging Machine

Overview

Chung Shan Machinery Works Co., LTD. is a professional manufactures of Packaging Machine, Powder Filling Machine, Granule Packaging Machine, Filling And Packaging Machine, Powder/Granule Packaging Machine and Automatic Quantitative Powder & Granule Filling & Packaging Machine.

Application

- Applicable Products:Various powder & granule, such as: sugar, salt, tea, grain powder, 2 in 1 coffee, 3 in 1 coffee, seasoning powder, milk powder, ground coffee, detergent powder, …etc.

- Applicable Film:Double layer heat sealable laminated film, such as: PET+LLDPE, PET+MPET+CPP, PET+PE+AL+LLDPE, Nylon+LLDPE…etc.

Features

- Servo motor with Touch panel for user friendly operation.

- Touch panel enable to set up: cutting mode (eye mark cutting or length cutting), packing speed, vibration, counter, sealing temperature, packaging data memory…etc.

- Two hopper loading to mix different products.

- Individual servo motor control for each part.

- Enable to operate one hopper according to request.

- Multiple memory programs to record/read different packaging data.

- Auto eye mark tracing in a short time.

- Auto warning display for quick trouble shooting.

- Convenient auto quantity warning function for efficient package.

- Machine build with auto calibration to have correct product filling & bag cutting position.

- Volumetric Filling method with metering dish & cups.

- All component in direct contact with product are made with SS304 or food sanitary standard.

- PID function Temp. controller for each sealing part with stable sealing performance.

- Bag width is adjustable by changing bag former guide.

- Bag length 50-200mm is adjustable on the panel directly.

- Machine build with iron cast with stainless steel frame.

- More hopper loading & vibration function available upon request.

Optional Device

- Date coder, hopper level indicator, product input/output conveyor, nitrogen air connector, height adjustable dish and other required device upon request.

-

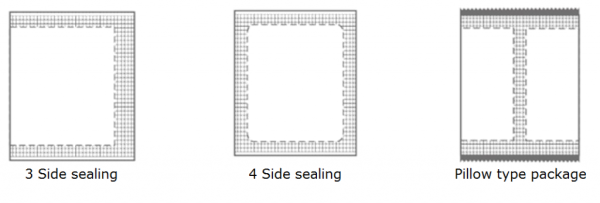

Sealing Type

Specification

| JS-12A Servo Type + Touch Panel + Two Hopper Loading |

| Sealing Style |

3 sides, 4 side or pillow type packaging(one option) |

| Motor |

Servo Motor |

| Power |

220V, 50 or 60 Hz, single phase(upon request) |

| Film Width |

60-160 or 80-220mm |

| Bag Length |

50-200mm |

| Filling Weight |

1-10g / 10-30g / 30-60g / 60-100g (varies with product density) |

| Packaging Speed |

About 20-50 bags/min |

| Machine Dimension |

195 x 155 x 225cm(L x W x H) |

| NET Weight |

480kg |

Other packaging sizes available upon request.

Filling weight& Packaging speed will be differ from product density, weight & film. |

Video

-

Related

-

Tags