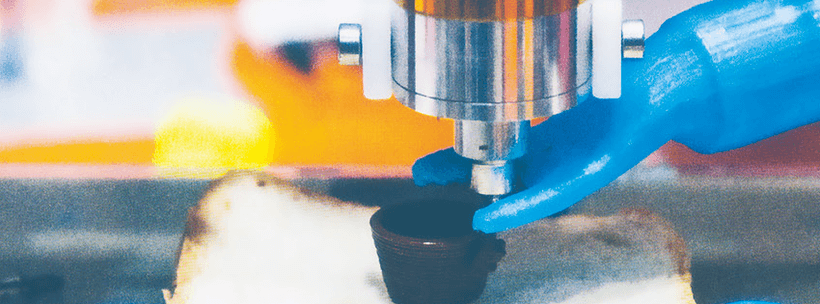

FOOD Printing in the third dimension: a reality?

What are we going to eat in the future? For years, they have been inventing new ways to prepare food and objects that make the question difficult to answer. Now it may seem strange, but the 3D food printing, still a new field, but in which important advances have been made, could bring great changes. - Tatiana Koutchma

Agriculture and Agri-Food Canada. Experience in Food Science.

Source: www.CarneTec,com

3D printing technology (3D) was originally invented to build metal, ceramic and polyester objects, and to perform the fabrication of complete structures in parts in one step. Today, 3D printing has also been successfully applied to food materials and is about to revolutionize food preparation, processing and manufacturing with customized skills in the design and development of products.

The potential applications of 3D printing include not only attributes, such as decorations, complex and geometric shapes, color, taste and elaborate texture, but also customized nutrition. Using simple ingredients, a food printer can formulate products based on personalized nutritional needs, and can provide a potential solution as a prototype tool to facilitate the development of a new food product. A new level of artistic capabilities can be achieved in restaurants and the culinary sector using 3D food printing technology.

-Food materials and 3D printing-

There are three categories of materials available that include food materials in native form (icing or bitumen for cakes, cheese, humus and chocolate), traditional non-printable food materials and alternative ingredients. In printing tests for traditional food materials, these have been evaluated for their viscosity, consistency and solidification properties. According to a large number of tests carried out, the most successful printing material was pasta dough. Foods, such as rice, meat, fruit and vegetables, are not printable by their nature. To allow its extrusion capacity, the addition of hydrocolloids in these solid materials has been used in many culinary fields.

Commercial and self-developed food printing platforms have been used to print and actually manufacture food products. A typical printing platform consists of a stage of X-Y-Z axes, dosing and sintering units and a user interface. There are several different methods and technologies for 3D printing: selective laser sintering and hot air, extrusion of heat-melted material or casting of the deposition, extrusion at room temperature, jet printing, and inkjet printing. Most of these processes already involve the deposition or melting of materials in a desired form, typically melting and solidifying the material used. With a computer controlled feeding system, such platforms can manipulate food manufacturing in real time.

The type and properties of materials and product that have to be manufactured determine the appropriate type of 3D printing technology. The technologies are grouped by the type of material used: dust, semi-solid, liquid, or cellular structures. The systems based on crops have been applied for the bio-printing of meat.

Both the laser and hot air methods can be used in a sintering source to melt the powder particles and form a solid layer. This method is only suitable for materials with sugar and fat base with a relatively low melting point. In the extrusion of heat-melted material, polymers, melted semi-solid foodstuffs are extruded from a movable head, solidified almost immediately after extrusion, and welded to the previous layers of the product. The extrusion method with hot temperature has been applied to create personalized 3D chocolate products. Extrusion at room temperature has been used for some printable native materials such as cheese, bitumen and humus.

In a jet feed, each powder layer is evenly distributed through the manufacturing platform, and a binder liquid is sprayed to bind two consecutive layers of powder. Prior to manufacture, a water spray layer is sprayed to stabilize the powder material and to minimize disturbances caused by the dispersion of the binder. Using sugar and different flavor binders, jet printing has been used to make structurally complex cakes for special events.

Inkjet printing deposits a sequence of edible ink droplets from a syringe-type print head on different product surfaces upon request. This type of printing has been used to decorate cookies and cakes, to make confectionery products or to fill surfaces. Jet printing is easily automated, suitable for mass production, offers customization possibilities and can be integrated into existing production lines. The disadvantages are short printing distances (<1 cm) and ink compatibility problems, since theoretically each food product would require a specific ink to have good print quality and ink adhesion.

The bio impression had originally been applied to build tissue and are not a platform based on biological material. This technique is based on the precise deposition of layer by layer of biological material and cultures of living cells. Droplets of freshly prepared multicellular aggregates (bio ink films) are deposited by means of an ink-jet nozzle in a compatible support structure. The final object is transferred to a bioreactor with the special purpose for maintenance and maturation. The "flesh" printed in this way could address the needs and find acceptance within the vegetarian community.

-Future needs-

Potential uses of 3D printed foods can be considered at three levels: food produced for the consumer, small-scale food production (shops, restaurants, bakeries), and food production on an industrial scale. Advances in 3D printing technologies can significantly change and improve the way food products are manufactured and produced. Any object can be scanned or designed with the help of a computer and design software, and then "sliced" into delayed layers, which can then be printed to form the product in three dimensions.

Substantial efforts have already been made to process suitable materials for printing and improving their thermal stability for further processing. Therefore, recipes used in food printing will have to be slightly different from traditional recipes. Even ingredients that contain well-known material properties need to be adapted for each printing application. Also, food safety concerns have greatly limited the application of technologies involving laser beams, electron beam, and unsafe food additives in food printing. Certified printers for food printing and which can easily be cleaned will need to be developed.

In 3D food printing, one of the questions that arise is whether it is safe. The security, according to the experts, depends on the device that is used. This must be specific for food, therefore, it should be easy to clean. If not, the risk of contamination by bacteria is high.

Like other production systems, one of the problems that appears is the accumulation of bacteria in the system. It is considered that even the best designed printers can have small spaces where the food can come to agglutinate and, therefore, bacteria can develop. Cleaning is essential in this aspect, since it will depend on it so as to avoid any formation of food residues. In addition, the ingredients that are used must have a consistency that allows them to be eliminated in their entirety by the system.

Another limiting factor in the adoption of 3D printing as an industrial food processing method is the speed of the process. 3D printing as a whole is a slow set of technology, which often require hours to produce large shapes. Among many other aspects, the development of the combination of food experience with new printing technologies is crucial for the ability to print on food or print food on an industrial scale.

Bibliographic references: - Sun, J. et al. 2015. An overview of 3D printing technologies for food fabrication. Food Bioprocess Technol., (2015) 8:1605-1615.

- Godol, F.C., Prakash, S., Bhandari, B.R. 3D printing technologies applied for food design: Status and prospects. Journal of Food Engineering (2016) 179: 44-54