Collaborations for circular food packaging: The set-up and partner selection process

Joana Kleine Jäger, Laura Piscicelli ∗

Copernicus Institute of Sustainable Development, Utrecht University, Princetonlaan 8A, Utrecht, 3584 CB, The Nether

|

Author Info

*Corresponding author. Received 22 August 2020, Revised 13 December 2020, Accepted 15 December 2020, Available online 17 December 2020. Editor: Prof. Ioannis Nikolaou

https://doi.org/10.1016/j.spc.2020.12.025 ©2020 The Author(s). Published by Elsevier B.V. on behalf of Institution of Chemical Engineers. This is an open access article under the CC BY license ( http://creativecommons.org/licenses/by/4.0/ ) |

Abstract

More than 40% of petroleum-based plastic materials produced are converted into packaging and half of those to food packaging. Around 95% of plastic packaging, however, is lost to the economy after a short first-use cycle and is often discarded in landfills or ends up in the natural environment. The circular economy is widely promoted as a solution to the current inefficient production, use, and disposal of plastic food packaging, most frequently via recycling or reuse. While the concept of circular food packaging has lately been taken up by policy and industry initiatives in Europe, its implementation remains limited due to the high degree of cross-chain collaboration required. Nevertheless, literature on collaboration in the circular economy is still scarce and provides little guidance on how to build up effective circular partnerships. This research aims to fill this knowledge gap by answering the research question: “How do focal firms set up and choose collaborations for circular food packaging?” A qualitative Delphi method was used to develop a theoretical framework based on collaboration literature and refine it by means of semi-structured qualitative interviews with 17 food companies operating in Europe and circular packaging experts. Results show that the process of identifying and establishing collaborations for circular food packaging typically follows nine steps, spread over five phases. The study also found fourteen possible partner roles and nine partner characteristics that are important in the selection and evaluation of potential partners for circular collaborations.

Keywords

1. Introduction

More than 40% of petroleum-based plastic materials produced are converted into packaging and half of those to food packaging (Rhim et al., 2013). Around 95% of plastic packaging (worth about US$80–120 billion), though, is lost to the economy after a short first-use cycle and is often discarded in landfills or ends up in the natural environment (Ellen MacArthur Foundation [EMF], 2017; Geyer et al., 2017). Such uncaptured waste represents an increasing concern due to its persistence and the negative effects of plastic marine debris on oceans, wildlife, and humans (Jambeck et al., 2015). In addition, plastic's after-use externalities generate significant economic costs; energy intensive plastic incineration and production processes contribute to climate change; and around 6% of the global oil production is consumed by plastic production (EMF, 2017; European Commission [EC], 2018; Geyer et al., 2017).

A circular economy – defined as “an economic system that is based on business models which replace the ‘end-of-life’ concept with reducing, alternatively reusing, [and] recycling […] materials in production/distribution and consumption processes” (Kirchherr et al., 2018, p.264) – is often promoted as a solution to the current inefficient production, use, and disposal of food packaging. As a regenerative system, a circular economy aims at slowing, closing, and narrowing material and energy loops (Bocken et al., 2016). Circular packaging solutions include redesigning packaging formats and delivery models, introducing reusable packaging, and improving the economics and quality of recycled plastic materials (EMF, 2017). Based on existing literature, reusable and recyclable food packaging are identified as common, feasible, and least controversial circular food packaging strategies (Schmidt Rivera et al., 2019; Pauer et al., 2019). While the concept of circular food packaging has lately been taken up by policy and industry initiatives in Europe (see EC, 2018), the reuse and recycling rates of food packaging still remain low. Contaminated, mixed materials and food-safety concerns often hamper the initial separation and sorting, as well as later recycling and reuse of primary packaging in direct contact with food (Davis and Song, 2006).

Recyclable food packaging requires effective post-consumer collection, sorting, and recycling processes implemented in practice and at scale, as well as financially attractive secondary material markets (EMF 2017; American Institute for Packaging and the Environment Ameripen, 2018). Due to the fragmentation and complexity of recycling value chains, improving the alignment between stakeholders and their interests is key for the development of recyclable food packaging (Hahladakis and Iacovidou, 2018). From all (potentially) recyclable materials, plastics represent a priority area since they are currently causing challenges throughout the value chain and their entire life cycle (EC, 2018; Hahladakis and Iacovidou, 2018). Plastic packaging, currently the most commonly used packaging material, shows low recycling rates due to a range of technical, economic, environmental, social, and legal issues (Kazulytė and Kruopienė, 2018; World Economic Forum (WEF), Ellen MacArthur Foundation (EMF), McKinsey & Company 2016). For instance, while mechanical recycling changes the structure of plastic polymers potentially causing downcycling and hindering repeated recycling, chemical recycling is not (yet) economically viable. Furthermore, hazardous chemicals in packaging, legal requirements for food-grade recycling, waste separation by consumers, collection and sorting represent common challenges. Addressing these challenges do not only ask for improved recycling technologies, but also for collaboration among all stakeholders of the supply chain. For instance, to design for recyclability, manufacturers need to ensure that packaging has an after-use value, which requires local working waste management systems (Kazulytė and Kruopienė, 2018; Geueke et al., 2018; Hahladakis and Iacovidou, 2018; Hopewell et al., 2009).

Similarly, major barriers towards the implementation of reusable food packaging systems lie in the reorganization of complex, global supply chains and relationships within those (Coelho et al., 2020). Reusable packaging “has been conceived and designed to accomplish within its lifecycle a certain number of trips, rotations or uses for the same purpose for which it was conceived” (International Organization for Standardization [ISO], 2016). Such a lifetime extension requires a systemic change in the way producers, retailers, and consumers operate. Within reusable food packaging, Coelho et al. (2020) distinguish between refillable packaging by bulk dispenser/parent packaging, returnable, and transit packaging. Formats of reusable food packaging are variable, including cleanable glass or stainless-steel containers (Geueke et al., 2018). Building on concerns that a truly circular economy cannot be achieved by recycling alone (cf. Haas et al., 2015), reusable food packaging contributes to a circular economy by decreasing materials or process impacts, while presenting untapped business potentials, for example by adapting to individual needs, improving the user experience, increasing brand loyalty, optimizing operations, integrating digital technologies, or cutting costs (Rigamonti et al., 2019; Ameripen, 2018; Ellen MacArthur Foundation EMF, 2019). At the same time, however, reusable food packaging is facing regulatory and security (e.g. tamperproofing) restrictions, high infrastructural and logistical requirements, and may collide with branding/marketing standards (Ameripen, 2018; Hopewell et al., 2009).

To overcome implementation barriers of both recyclable and reusable food packaging, joint forces via collaborations outside of and along the value chain are needed (Clark et al., 2019; EMF, 2017). In this way, information insufficiencies, poorly coordinated and fragmented local initiatives, and the lack of communication between packaging producers/designers and waste management – which often slows down the development of innovative solutions – can be overcome (Ordoñez and Rahe, 2013). Within the collaborative process, the initial task of selecting partners and establishing collaborations is considered a major collaboration-specific challenge determining later success and potential issues (Solesvik and Westhead, 2010; Kelly et al., 2002; Brown et al., 2018). During this initial phase, however, firms may act on unfamiliar territory, lack clear reference frames, or encounter cultural differences and tensions (Kelly et al., 2002). Moreover, the collaboration choice criteria (e.g. partner type and characteristics) and set-up process have not been specifically analyzed in the circular economy context (Lahti et al., 2018; Brown et al., 2018), thus providing companies with little to no guidance for establishing effective cross-chain partnerships. This research aims to fill this knowledge gap by answering the research question: “How do focal firms set up and choose collaborations for circular food packaging?” As collaboration helps overcome obstacles towards implementing circular food packaging, food companies can benefit from such insights and resulting practical advice. Furthermore, this study extends existing research on circular food packaging by providing valuable empirical knowledge on (supply chain) management practices. Finally, this research contributes to circular economy literature, where collaborative approaches and particularly the collaboration choice and set-up process are barely covered.

In the next section, existing literature on the collaboration set-up process and partner selection is reviewed to build the initial theoretical framework that will be refined by means of the empirical study. Section 3 describes the methodology adopted in this study. Results are presented and discussed in Section 4. Section 5 concludes the paper by providing an account of its key findings and managerial implications, and acknowledging the study's main limitations as well as avenues for future research.

2. Literature review

The creation of collaborative networks is acknowledged in the literature as a key driver towards a circular economy (Brown et al., 2018; De Angelis et al., 2018; Dora, 2019; Farooque et al., 2019; Leising et al., 2018; Mishra et al., 2019; Ruggieri et al., 2016; Witjes and Lozano, 2016). Businesses pursuing collaborative endeavors can overcome common circular economy inhibitors such as less accessible and expensive technology, lack of clear guidance and consensus, high upfront investment, or regulatory uncertainty (Mishra et al., 2019; Brown et al., 2018). Compared to linear operations, the need for collaboration is even increased in a circular economy since, for instance, industrial symbiosis collaborative partnerships allow waste from a supply/process chain to become a resource for another one (De Angelis et al., 2018; Fraccascia et al., 2019).

Collaboration is considered here as an umbrella term, broadly understood as “joint planning, joint implementation and joint evaluation between individuals or organizations” (Shirley 1981, p.6). In the context of a circular economy, collaborations encompass different forms of cooperation along (vertical) and outside (horizontal) the value chain, as well as firm-internal collaboration. To realize circular food packaging, for example, focal firms need to set up internal cross-functional teams and collaborate with external partners in terms of industrial symbiosis, pursuing common goals, and exchanging knowledge (Clark et al., 2019). For circular food packaging, collaboration allows packaging design/prototypes to reach viability, legal compliance, and consumer trust. Likewise, sharing platforms for reusable food packaging or new recycling technologies can be developed by means of cross-chain collaborations with a variety of stakeholders (Guillard et al., 2018; Meherishi et al., 2019; Brown et al., 2019).

Nonetheless, not only studies on collaborative circular economy supply chain relationships are lacking (Dora, 2019), but in particular approaches enabling collaborative circular food packaging call for further research (Meherishi et al., 2019). Additionally, when reviewing literature on the collaboration choice and set-up, circular economy-specific insights are limited. Thus, traditional and sustainability collaboration literature is additionally reviewed in this section to develop a preliminary theoretical framework.

2.1. Collaboration set-up process

In the course of the collaboration set-up, firms choose attractive partners in terms of “the degree to which the initiating firm in a particular alliance project sees a partner as desirable, favorable, appealing, and valuable” (Shah and Swaminathan, 2008, p. 473). This set-up process commonly represents a root of (later) collaborative obstacles and is characterized by difficulties (Kelly et al., 2002). To circumvent those, the precondition stage of the collaboration success measurement model by Czajkowski (2007) outlines a series of steps to be taken. Other collaboration literature proposes similar frameworks (e.g. Kelly et al., 2002; George and Farris, 1999; Bryson et al., 2015; Duysters et al., 1999). Moreover, Brown et al. (2019) introduce key steps of collaborative circular oriented innovation. Overall, it is possible to identify in the existing literature six main consecutive collaboration set-up steps: (1) recognition of the need and potential benefits of collaborating, e.g. a problem insoluble alone, risk spreading, additional resources/capabilities (George and Farris, 1999; Czajkowski, 2007; Bryson et al., 2015); (2) development of the vision, goal, and criteria for partner selection (Duysters et al., 1999; Czajkowski, 2007; Brown et al., 2019); (3) internal development of required skills and commitment to human resources, including a collaborative mind-set, orientation towards learning, ability to share and absorb knowledge/skills (Duysters et al., 1999; Bryson et al., 2015); (4) analysis of the external business environment and potential partners, i.e. “roadmapping” breaks down scenarios to milestones and can indicate needed competencies and necessary steps to reach those (Rohrbeck et al., 2013; George and Farris, 1999; (Duysters et al., 1999); Czajkowski, 2007); (5) partner assessment and selection (see Section 2.2); and (6) informal and formal agreements with partners (Kelly et al., 2002; Czajkowski, 2007; Duysters et al., 1999; Bryson et al., 2015; George and Farris, 1999).

2.2. Partner selection

In the fifth step of the ideal collaboration set-up process described above, Geringer (1991) distinguishes task-related roles (i.e. knowledge, skills, resources, competences, network links, influence) and partner-related characteristics (i.e. cultural, procedural, systemic fit) as selection criteria to choose attractive partners. Regarding the latter, Kelly et al. (2002) argue that relational criteria often tend to be forgotten but are key to mutually successful alliances. Since circular economy or sustainability specific partner characteristics are not discussed in extant literature, partner selection criteria of traditional collaboration literature are taken into consideration, resulting in eight main characteristics: (1) strategic fit, e.g. between the market, strategy, management, or geography (Solesvik and Westhead, 2010; Dietrich et al., 2010); (2) goals alignment to enable information exchange, incentives alignment, mutual benefits, and shared risks (Barrat, 2004; Dietrich et al., 2010); (3) (financial) advantageousness (Shah and Swaminathan, 2008; Solesvik and Westhead, 2010); (4) good reputation within an industry (Solesvik and Westhead, 2010); (5) enthusiasm (Solesvik and Westhead, 2010); (6) (collaborative) commitment as willingness to supply tangible resources (Dietrich et al., 2010; Shah and Swaminathan, 2008); (7) trustworthiness, in particular among the top management teams (Shah and Swaminathan, 2008; Dietrich et al., 2010; Barrat, 2004; Solesvik and Westhead, 2010); and (8) open communication, i.e. the ability and willingness to drive transparent and honest information flows (Barrat, 2004). Complementarity could be considered an additional partner characteristic. In this study, however, it is equated to task-related selection criteria, i.e. partner roles.

Eleven roles of relevance for circular food packaging can be distinguished as second set of partner selection criteria, which build on the roles identified by Goodman et al. (2017) in sustainable innovation processes, case study evidence on partner selection for strategic alliances by Solesvik and Westhead (2010), and the classification of circular players proposed by Brown et al. (2019). Those roles address either, or both, research and business purposes, since food firms striving towards circular food packaging commonly need to combine those purposes. The roles can be assigned to three different collaboration stages: starting, developing, or realizing the project. In the first stage, the initiator inspires and generates ideas for an innovation (Goodman et al., 2017); whereas the financier provides direct or indirect funding (Solesvik and Westhead, 2010; Brown et al., 2018; Goodman et al., 2017). In the developing stage, the piloter/refiner develops, tests, and enhances products/services (Solesvik and Westhead, 2010; Goodman et al., 2017; Brown et al., 2018), while the closed loop material expert supports the “development of closed network functions for materials” (Brown et al., 2018, p. 193). In the last stage – realizing the project – the use-phase supporter facilitates the product-life-extension (Brown et al., 2018), and the impact extender promotes the increased usage of products/services (Goodman et al., 2017). The remaining roles are either related to the collaboration process or address stakeholders outside the value chain. In the first case, the mediator integrates stakeholders and creates networks (Goodman et al., 2017), whereas the knowledge broker engages in collaborations for joint learning (Brown et al., 2018). In the second case, the enabler has regulatory, market, and political knowledge and influence (Solesvik and Westhead, 2010; Goodman et al., 2017); the educator changes the perception and behavior of the public (Goodman et al., 2017); and the legitimator creates credibility via assurance and promotion (Goodman et al., 2017).

3. Methods

This exploratory study aims at identifying the typical collaboration set-up process of focal food firms for circular food packaging alongside the partner selection criteria applied in terms of roles and partner characteristics. To do so, a qualitative Delphi method is adopted since the approach: a) makes it possible to leverage the knowledge of a group of experts on a topic to understand a phenomenon in greater depth; b) can be used for concept/framework development; and c) is suitable for studies whose research questions and aims are intended to inform practice (Brady, 2015; Fletcher and Childon, 2014; Okoli and Pawlowski, 2004). More specifically, a theoretical framework on the collaboration set-up process, partner roles, and partner characteristics is first developed based on traditional and, when available, circular economy and sustainability collaboration literature. Second, the framework is probed with circular food packaging experts. Finally, a refined framework is elaborated. The scope of the research was limited to reusable and recyclable primary retail food packaging in North-Western Europe: empirical evidence stems from the Netherlands, Germany, the UK, France, and Switzerland. This geographical scope makes it possible to gather descriptive empirical evidence (Bryman, 2012) with relatively advanced circular food packaging initiatives. Moreover, social, political, and economic factors are relatively comparable. Primary packaging in direct contact with food is of interest in this study since reuse and recycling pose a larger challenge for primary packaging compared to secondary or tertiary packaging. Hence, improvements in these areas are key (Davis and Song, 2006). Since packaging avoidance is generally more desirable than reusable or recyclable food packaging, food items not necessarily requiring packaging are excluded from the investigation. Qualitative interviews (Eisenhardt, 1989) were preferred over a quantitative inquiry in order to uncover practices and experiences in the circular food packaging field and support the theory refinement in a descriptive manner. By means of a three-step general purposive sampling strategy, 17 interviewees were chosen based on their: (1) work on reusable and/or recyclable food packaging; (2) insights on focal food firms’ processes; and (3) knowledge on the collaboration choice and set-up process for circular food packaging. The sample included three food-products multinational corporations (MNCs; M1-M3), two food-products small and medium-sized enterprises (SMEs; S1-S2), four food retailers (R1-R4), and two reuse service providers (U1-U2) (see Table 1). The variety of interviewees included in the sample made it possible to examine contrasting elements, namely: reusable vs. recyclable food packaging; retailers vs. food producers; and SMEs vs. MNCs. Subsequently, six circular food packaging experts (E1-E6) were interviewed with the aim to test, extend, and better understand the insights gathered in the first round of interviews. The semi-structured interviews had an average length of 60 minutes and were conducted in the last quarter of 2019. To enhance their comparability and reliability, two interview guides based on the theoretical framework originally developed were used (see Supplementary material). As guidance, visualizations of the theoretical framework (set-up process, partner roles, partner characteristics) were shared with the interviewees during the interview. Open-ended questions were used to gain specific details of the experiences, beliefs, and learnings of the interviewees.

Table 1. Interviewee profiles.

| Interviewee | Organization type | Function in the organization |

|---|---|---|

| E1 | Recyclability initiative | Sustainable packaging consultant |

| E2 | Consulting and assurance firm | Sustainability senior manager |

| E3 | Circular Economy consultancy | Founder, circular economy consultant |

| E4 | Circular Economy consultancy | Sustainable packaging consultant |

| E5 | Sustainable packaging organization | Sustainable packaging expert |

| E6 | Sustainable packaging organization | Sustainable packaging expert |

| M1 | Food-products MNC | Circular economy packaging director |

| M2 | Food-products MNC | Sustainable packaging senior manager |

| M3 | Food-products MNC | Sustainability and circular economy manager |

| S1 | Sustainable SME food producer | Founder |

| S2 | Sustainable SME food producer | Manager |

| R1 | Multinational retailer | Sustainable packaging specialist |

| R2 | Multinational retailer | Sustainability specialist |

| R3 | Retailer | Innovation and sustainability specialist |

| R4 | Organic SME retailer and wholesaler | Communication & PR specialist |

| U1 | Reusable packaging service provider | Founder, manager |

| U2 | Reusable packaging service provider | Co-founder, advisor |

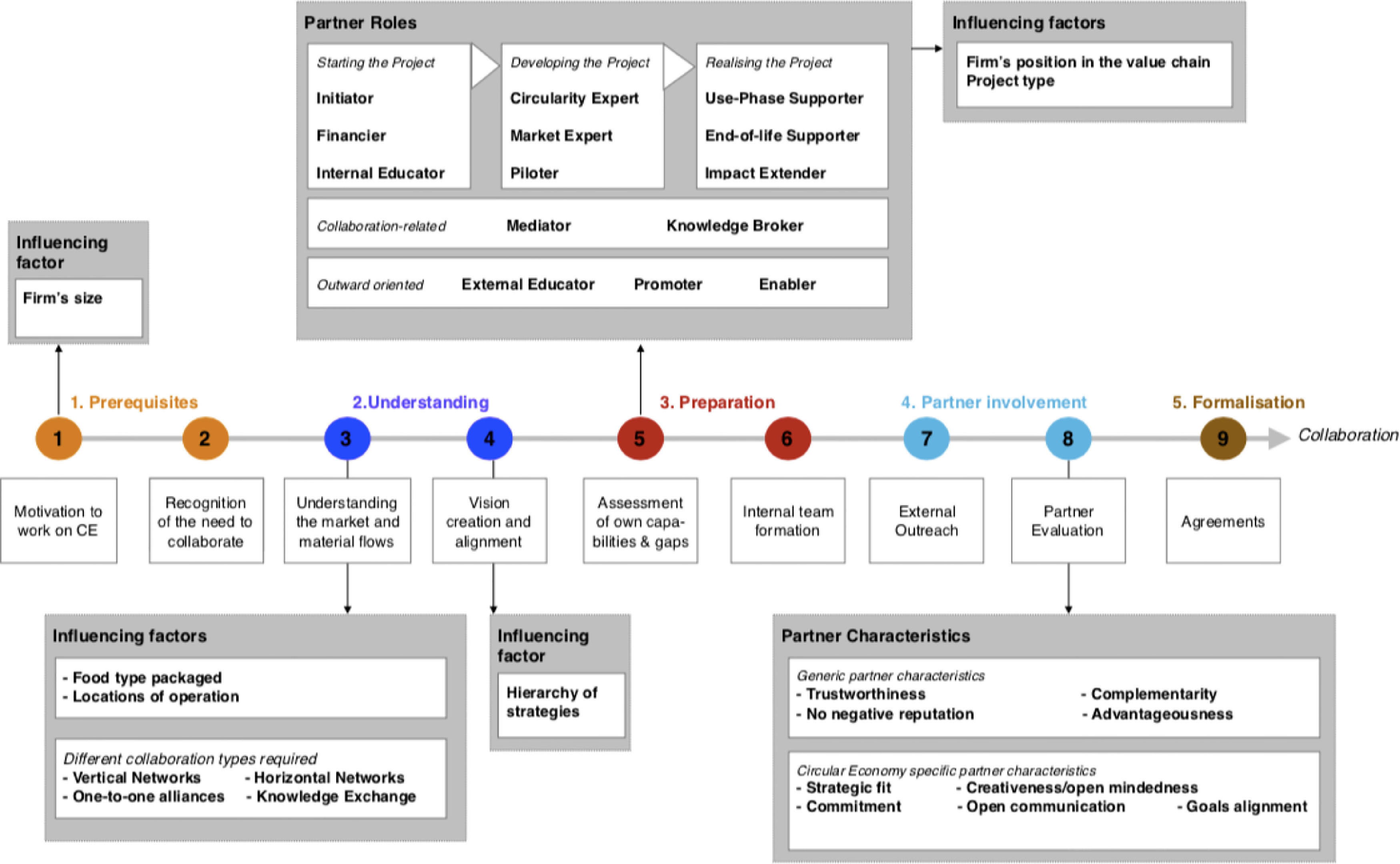

All but one interview were recorded and fully transcribed. With the help of NVivo, the data were coded and analyzed using thematic analysis techniques (Brady, 2015). The analysis started with open coding rounds, gradually focusing, ending with axial coding (Corbin and Strauss, 1990). Theoretical saturation was reached after three coding rounds. To explore connections, for instance between partner types and roles, single pieces of data were coded to several concepts, i.e. coding a mentioned player not only under the respective partner type but also performed role. Categories and sub-categories were developed in an iterative, progressive manner, and were used for testing and eventually refining the original theoretical framework. Strict coding rules were applied by constantly comparing the interview data to emerging theoretical categories (Bryman, 2012). The modified framework (see Fig. 1) brings together the collaboration set-up process, partner roles, partner characteristics and includes the collaboration types as well as the influencing factors additionally identified by means of the interviews.

Fig. 1. Revised framework: Collaboration set-up process and partner selection for circular food packaging.

4. Results and discussion

Results suggest that food companies necessarily require collaborations for circular food packaging, since they cannot fulfill all tasks (i.e. roles) internally. The type of partners sought for, however, differs between companies. In addition, the data provide insights into partner characteristics of importance, the typical collaboration set-up process followed, and factors influencing this process. This section introduces the refined theoretical framework and substantiates it with quotes from the interviews. Results provide empirical evidence for all six set-up steps originally identified, seven of the eight partner characteristics, and all eleven roles included in the preliminary framework. Yet, the findings go beyond existing collaboration and circular economy literature by identifying three novel set-up steps, two partner characteristics, and three partner roles; and revising two set-up steps, one partner characteristic, and three partner roles. As a result, this section proposes a collaboration choice and set-up framework (Fig. 1) to facilitate the realization of collaborations for circular food packaging. Since “there is no ideal process” (S1) these set-up steps represent a typical rather than a fixed process.

4.1. Prerequisites phase

Results provide evidence for an initial ‘prerequisites phase’ in the collaboration set-up process, of which the first step, the motivation to work towards a circular economy, appears to be influenced by the size of the food firm. In particular, MNCs seem to be generally more motivated due to resources available, unless a SME's whole strategy is oriented towards sustainability: “For this [working with the government and educational institutions towards recyclability], the company is not big enough, we do not even have an R&D department for that. A [large food brand] can afford such things, they obviously all have that now” (R4). Moreover, within firms, an internal lead, who drives circular economy initiatives, can represent an important motivator (cf. Lueneburger and Coleman, 2010).

As a second step, in line with collaboration literature, firms have to recognize the need and potential benefits to collaborate for circular food packaging. Interviewees confirmed that this awareness would usually be present: “[Collaboration] is by default part of all of our roadmaps for sustainability topics” (M3). The data indicate that this need is higher for recyclable food packaging, where competitors jointly establish and use waste management systems. For reusable food packaging, collaboration can enhance its economic viability, but service providers often act as orchestrators, bypassing collaboration between competitors.

4.2. Understanding phase

In the ‘understanding phase’, this research identified the step of understanding the market and material flows. While interviewees agreed that this analysis would usually not follow a pre-defined approach, still, it provides the basis for well-informed partner choices and enables negotiations. This third step informs all subsequent ones and is thus important earlier in the process than assumed in the existing literature. For circular food packaging, firms need to understand the possible product-packaging combinations suitable for the specific food. This, as well as the location of operation, influences the collaborations required. Findings also suggest that different collaboration types are necessary depending on the development stage of the local reuse/recycling system. Four types are identified: a) vertical networks aiming to develop the packaging reuse/recycling system when this is not yet in place or well-functioning, b) horizontal networks to develop new materials for/utilize existing systems, and c) one-to-one alliances to improve packaging or technologies. Irrespective of the system's development stage, food companies also employ d) informal collaborations for knowledge exchange.

In line with collaboration literature, as a fourth step, most firms were found to develop a circular food packaging vision and strategy to “adapt your resources where you want to be” (M2). Comparing circular economy strategies, firms may take the hierarchical ladder of resource value retention options (“R-hierarchies” or “R-framework”; see also Reike et al., 2018) into account. Generally, interviewees favored reusable over recyclable food packaging in terms of system impact. The analysis shows that to realize a circular food packaging vision, top management support as well as alignment of the circular food packaging vision and strategy across the firm is required. Since changes towards circular business logics might be radical and cause organizational inertia (Lahti et al., 2018), firms require flexibility, early transparent communication, and the exertion of influence: “In every revolution it takes two generations, why? Because the mindsets need to change” (R2).

4.3. Preparation phase

In the ‘preparation phase’, food companies were found to assess internal capabilities and gaps in order to identify potential partners with complementary resources and capabilities (cf. Dyer and Singh, 1998). This study introduces 14 roles (see Fig. 1), which food companies or their partners may fulfill to realize circular food packaging, of which three (‘internal-educator’, ‘market-expert’, ‘end-of-life supporter’) were added and three (‘impact extender’, ‘enabler’, ‘promoter’) slightly amended compared to previous literature. The three roles associated to the project's realization phase are found to be the most important and, thus, require the fulfillment of all nine identified partner characteristics introduced later (Section 4.4). While brands can fulfill all roles except the ‘end-of-life supporter’, retailers never take up seven of the fourteen possible roles. One interviewee explained: “If someone kicks [retailers] with the broom then they move. […] They truly see the urge for them to move, but they will not move any faster than it's needed. Whereas [there are] some of the major brands that are really out there, stating ambitions and doing the extra mile. That's totally different” (E3).

Besides the position in the value chain, the type of partners sought after appears to differ based on the project type. For recyclable food packaging, roles of importance mirror the identified challenges being of technical, legal/safety, or economic nature. The ‘financier’ can provide/enable (in)direct financing. Governments should create “completely different financial structures for collection, sorting, recycling” (E4). Building on Brown et al. (2018), the ‘circularity expert’, identified by the interviewees as too little represented in practice, advises and supports the development of recycling networks, potentially in the form of working groups/consortia: “The main benefit [of the consortium] is education, understanding where we will be going, but we also run webinars for the stakeholders and we provide advice, documentation. There's knowledge coming out of each of the work streams” (E1). Third, the newly identified ‘end-of-life supporter’ is relevant for recyclable food packaging with shorter lifetimes. To improve packaging's end-of-life treatment, brands but also retailers frequently endorsed extended producer responsibility (EPR) schemes: “That's why we are pushing for EPR, because it will allow us to have a level playing field, and then it's not just a few or couple of companies contributing, but it's everybody” (M3). Reusable food packaging requiring new service-oriented business models calls for three other major roles. In line with Goodman et al. (2017), consumers promoting circular food packaging can act as ‘impact extender’: “I think that the reusable business will mainly be driven by the what I will call the dark-green or light-green consumers” (M2). In addition, most interviewees advocated for a pre-competitive circular economy approach between competing companies to address shared problems (cf. De Angelis et al., 2018). Second, the ‘promoter’ can communicate and promote circular food packaging products to establish credibility and publicity: “People [should] get used to it, so they only go to the supermarket when they bring their glass jar” (S1). Finally, in line with Brown et al. (2018), the ‘use-phase supporter’ establishes, operates, and utilizes value chain networks to extend packaging's life. This role is frequently performed by reuse system providers with innovative, service-oriented reuse models. The findings back up literature (cf. Ameripen, 2018) pointing towards a shortage of this actor.

Besides differences between project types, the findings highlight three circular economy-enabling roles. First, the ‘mediator’ connects different actors to build one-to-one collaborations or networks. Second, the ‘knowledge broker’ manages collaborative processes and research outcomes: “We really need players that can see other trends and developments within different sectors, linking it, and actually driving that project forward, because it's a very different thinking then within a company or within a value chain. If you're talking about cross-value-chain coalitions, I've only seen it work if there was an external project leader” (E3). In keeping with Brown et al. (2018), this actor benefits from good networks and circular economy knowledge, i.e. actors combining the ‘knowledge broker’ and ‘circularity expert’ are powerful. Both the ‘knowledge broker’ and ‘mediator’ are identified as actors currently lacking. Third, the ‘enabler’ (co-)creates, steers, and pushes legislation, norms, and the market towards circular food packaging. Interviewees stated that cooperation between politics and businesses can enable joint regulatory circular economy changes, while reducing regulatory uncertainties (cf. Clark et al., 2019). To ease the uptake of circular food packaging, some interviewees called for European-wide legislation. Moreover, this research identified two circular economy-educating roles of importance as a circular economy requires a novel economic system: the ‘external educator’, who instructs individuals holding powerful positions and consumers as indispensable actors in a circular economy (Goodman et al., 2017; Kirchherr et al., 2018): “Yes, education everywhere. But you need kind of an education, maybe some basic one for people to understand that circular economy is different than just doing less bad and reducing impacts” (M2). Furthermore, the newly introduced actor ‘internal educator’ disseminates and transfers knowledge within firms. Some interviewees argued that food companies would devote too little effort to this task. Finally, three roles are found to be generally important, rather than circular economy-specific: the either idea-spreading, pressure-creating, or action-oriented ‘initiator’; the ‘piloter’ developing, piloting, and improving technologies or circular food packaging systems; and the newly identified ‘market expert’ with market-related and consumer knowledge: "We need to understand what drives the behavior and how we can change it, what we do to ensure that we bring customers on the journey with us” (R1).

As a sixth step, companies were found to typically form a team internally. In contrast to existing collaboration literature, food companies do not appear to require internal alliance building skills, but employees need collaborative skills, expertise on circular food packaging, and the ability to deal with uncertainties and complexities. Despite MNCs could hire circular food packaging specialists (which is often not possible for SMEs), particularly retailers would rarely do so. Furthermore, in accordance with Lahti et al. (2018), this study identifies setting up steering committees to handle difficulties in collaborative circular food packaging projects as a helpful tool.

4.4. Partner involvement phase

As part of the ‘partner involvement phase’, the external outreach (step seven in Fig. 1) frequently came up in the interviews, while rarely being addressed in collaboration literature. Although firms prefer prolonging existing relationships due to relation-specific investments and knowledge sharing routines (cf. Dyers and Singh, 1998), this research found that for circular food packaging some new partners are needed compared to linear food packaging (cf. Lahti et al., 2018). During this step, the earlier introduced ‘mediator’, who connects different players, may play a role.

The data show that, subsequently, companies generally evaluate potential partners in regard to their desirability, favorability, appeal, and value (cf. Czajkowski, 2007; Shah and Swaminathan, 2008) to choose compatible ones. In response to the absence of an understanding of circular economy partner types (Brown et al., 2019), alongside the introduced roles, this study introduces partner characteristics assisting in the evaluation. One characteristic included in the preliminary framework (Section 2.2), ‘enthusiasm’, was discarded from the refined framework (Fig. 1) since it proved to be less relevant than assumed by extant literature: some interviewees classified it as a potentially temporary, person-related, not action-oriented state. Beyond excluding this characteristic, this research not only defines nine important partner characteristics, but goes further to show which are generic and which circular economy-specific. Three characteristics are paramount in a circular economy. First, for circular food packaging, a ‘strategic fit’ is important, including the circular food packaging vision, company culture, context, or geographical proximity for material exchange collaborations: “They [our partner] really work for everything that we embody, on our set of requirements, our own needs” (S2). Second, it was found that ‘creativeness/open mindedness’ is key since circular food packaging usually entails collaboration in multiplayer networks, complexities, and uncertainties. This characteristic has not been highlighted by existing collaboration literature. Similarly, however, Rohrbeck et al. (2013), Lahti et al. (2018), and Pieroni et al. (2019) call for creativity and open-mindedness when conceptualizing circular business models. Third, ‘open communication’ to enable collaborative learning as continuous, reciprocal achievement was named as a desired norm in some interviews (cf. Clark et al., 2019). In this way, progression, company advantages, and the reduction of uncertainties could be enabled. Moreover, this study identified two other characteristics as baseline for circular economy collaborations. Since in a circular economy value is generated in synergetic interrelationships, and uncertainties and difficulties ask for flexibility, “that flexibility will arise if they [your partners] are aligned with your mission” (U2), i.e. ‘goals alignment’ is important. Second, due to mutual dependence and reciprocity in a circular economy (cf. Lahti et al., 2018), ‘commitment’ in terms of wanting the change and investing resources was frequently mentioned. The findings indicate that progressive organizations tend to be more committed since realizing circular food packaging requires additional time and monetary investments, while pay-offs are rather long-term. Finally, results highlight four characteristics found in the collaboration literature as generic partner characteristics: ‘complementarity’ (which is covered under partner roles in this study), e.g. to “be able to perform what is needed” (E3); financial ‘advantageousness’, representing one of the three circular economy priorities (i.e. financial advantages for companies, lower resource consumption, and less pollution for the environment; see also Geissdoefer et al., 2017); ‘no negative reputation’ rather than a necessarily good reputation; and ‘trustworthiness’ in terms of (individuals within an organization) adhering to promises due to common mutual dependences and relation-specific investments in a circular economy.

4.5. Formalisation phase

In the final ‘formalisation phase’, this study confirms literature calling for informal (e.g. collaborative goals, division of roles) and formal (e.g. financial and confidentiality related) agreements to establish collaborations with partners chosen based on their roles and characteristics. The findings highlight that reaching full consensus in multiplayer collaborations for circular food packaging may neither always be possible nor needed when objectives, impacts, or costs between partners differ. The management, contract/transaction design, and administration of novel circular economy collaborations, however, call for further exploration (cf. Korhonen et al., 2018; Meherishi et al., 2019; Fischer and Pascucci, 2017; De Angelis et al., 2018; Lahti et al., 2018).

5. Conclusions

As a response to the current inefficient production, use, and disposal of food packaging, focal food firms are important actors for the realization of circular food packaging. As central players, they can wield power over the supply chain and, by collaborating, overcome existing implementation challenges. Through the comprehensive analysis of the collaboration choice and set-up process of food companies, a theoretical framework was developed and refined (Fig. 1), providing insights into the collaboration set-up steps, partner roles, partner characteristics, collaboration types, and influencing factors. Findings show that food firms typically follow nine steps when establishing collaborations for circular food packaging. Since they cannot fulfill all tasks internally, they require collaborative support. The importance of the 14 specified circular economy roles, of which 11 are by far more important or additionally needed in the context of circular food packaging compared to traditional collaborations, is found to be influenced by the firm's position in the supply chain, the project type (here reusable vs. recyclable food packaging), the firm's size, and the product (here properties of the food). Moreover, based on the development stage of the local reuse or recycling system, four different collaboration types (i.e. vertical networks, horizontal networks, one-to-one alliances, informal alliances) appear to be required. The framework also encompasses nine characteristics to choose compatible partners, five of which are shown to be of particular relevance in a circular economy.

The findings of this research have some important (supply chain) managerial implications, which increasingly need to complement technical circular food packaging explorations. Firms that want to move towards circular product offers, such as circular food packaging, are facing complexities and uncertainties on how and with whom to establish collaborations. This research may be of interest to these firms, but also other circular economy stakeholders, by providing them with guidance on how to find and set-up collaborations for circular food packaging. By understanding roles of importance in a circular economy, specifically for reusable and recyclable food packaging, firms can identify and enhance their own capacities while being informed about required (additional) partners to realize circular food packaging. Based on these insights, they can establish new suitable collaborations, while maintaining already existing ones, in order to reach identified circular food packaging targets.

Despite the promising contributions offered to the circular economy collaboration and circular food packaging field, this study has some limitations that need to be acknowledged. First, within the geographical scope, but even more in other geographies than North-West Europe, differences can be expected. While North-West Europe has, for instance, relatively advanced recycling systems, at the same time, compared to other geographies, disposable, convenient packaging became a norm. Therefore, reusable packaging may be more common and accepted by consumers in other areas such as Central or Eastern Europe. Similarly, the collaboration choice and set-up process may differ in the four collaboration types identified, as well as between different models and packaging formats of reusable and recyclable food packaging. The external validity of the results is also limited due to the sample size of 17 interviewees. However, expert-interviews were included to enhance the generalizability of the findings.

Future research could validate the framework for other geographical contexts and other circular economy fields than circular food packaging. Many identified elements of the proposed framework likely hold true for any collaborative circular economy project; still, this is to be confirmed and possible differences need to be empirically determined. Furthermore, specific elements such as the influencing factors, the collaboration types, or the role of SMEs in circular food packaging collaborations, often falling short in MNC-driven initiatives, could be investigated. For instance, the role of and influence on collaboration of the ‘enabler’ will become apparent in the coming year 2021, when the plastic tax on nonrecycled packaging waste will be introduced in Europe. This tax most likely will influence the dynamics on the recycled material market and, hence, also the type of collaborations needed. For instance, food companies may need to increasingly collaborate with ‘end-of-life supporters’ to improve recycling technologies, which may require a pre-competitive approach in terms of collaborating with ‘impact extenders.’ Moreover, the relation between partner roles and characteristics, as well as typical combinations of roles were only broached in this study. An in depth-analysis of those could be conducted. In addition, future research could focus on the collaboration realization phase, including the underlying governance mechanisms. Similarly, possible learning and transformation processes of organizations aiming to perform the identified characteristics is worth of further investigation. Finally, based on the proposed framework, practical tools to guide practitioners could be developed, for example in the form of a guided collaboration set-up workflow process, a gap analysis to identify partner roles of importance, or an evaluation checklist to assess potential partners’ characteristics.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary materials

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.spc.2020.12.025 .

References

Barratt, M. , 2004. Understanding the meaning of collaboration in the supply chain. Supply Chain Manage.: Int. J. 9 (1), 30–42 .

Bocken, N.M.P. , de Pauw, I. , Bakker, C. , van der Grinten, B , 2016. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 33, 308–320 . Brady, S.R. , 2015. Utilizing and adapting the Delphi method for use in qualitative research. Int. J. Qual. Methods 14 (5), 1–6 .

Brown, P. , Bocken, N. , Balkenende, R. Moratis, L., Melissen, F., Idowu, S.O. (Eds.), 2018. Towards understanding collaboration within circular business models. Sustain. Business Models 169–201 .

Brown, P. , Bocken, N. , Balkenende, R. , 2019. Why do companies pursue collaborative circular oriented innovation? Sustainability 11 (3), 635 .

Bryman, A. , 2012. Social Research Methods, 4th ed. Oxford University Press, Oxford; New York .

Bryson, J.M. , Crosby, B.C. , Stone, M.M. , 2015. Designing and Implementing Cross-Sec- tor Collaborations: needed and Challenging. Public Adm. Rev. 75 (5), 647–663 . Clark, N. , Trimingham, R. , Storer, I. , 2019. Understanding the views of the UK food packaging supply chain in order to support a move to circular economy systems. Packag. Technol. Sci. 32 (11), 577–591 .

Coelho, P.M. , Corona, B. , ten Klooster, R. , Worrell, E. , 2020. Sustainability of reusable packaging–current situation and trends. Resour. Conserv. Recycl. X 6, 10 0 037 . Corbin, J.M. , Strauss, A. , 1990. Grounded theory research: procedures, canons, and evaluative criteria. Qual. Sociol. 13, 3–21 .

Czajkowski, J.M., 2007. Leading Successful Interinstitutional Collabora- tions Using the Collaboration Success Measurement Model Retrieved from http://chairacademy.com/conference/2007/papers/leading_successful _interinstitutional_collaborations.pdf .

Davis, G. , Song, J.H. , 2006. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crops Prod. 23 (2), 147–161 .

De Angelis, R. , Howard, M. , Miemczyk, J. , 2018. Supply chain management and the circular economy: towards the circular supply chain. Prod. Plann. Control 29 (6), 425–437 .

Dietrich, P. , Eskerod, P. , Dalcher, D. , Sandhawalia, B. , 2010. The dynamics of collabo- ration in multipartner projects. Project Manage. J. 41 (4), 59–78 .

Dora, M. , 2019. Collaboration in a circular economy: learning from the farmers to reduce food waste. J. Enterprise Inf. Manage. 33 (4), 769–789 .

Duysters, G. , Kok, G. , Vaandrager, M. , 1999. Crafting successful strategic technology partnerships. R&D Manage. 29 (4), 343–351 .

Dyer, J.H. , Singh, H. , 1998. The relational view: cooperative strategy and sources of interorganizational competitive advantage. Acad. Manage. Rev. 23, 660–679 . Eisenhardt, K.M. , 1989. Building theories from case study research. Acad. Manage. Rev. 14 (4), 532–550 .

Ellen MacArthur Foundation (EMF), 2017. The New Plastics Economy. Re- thinking the Future of Plastics & Catalysing action Retrieved from https://www.ellenmacarthurfoundation.org/assets/downloads/New- Plastics- Economy_Catalysing- Action_13- 1- 17.pdf.

American Institute for Packaging and the Environment (Ameripen) (2018). Packaging Materials Management Definitions: A Review of Varying Global Standards. Guidance Document. Retrieved from https://cdn.ymaws.com/www.ameripen. org/resource/resmgr/pdfs/AMERIPEN- Report- RecyclingDef.pdf [Accessed 25 May 2020].

Ellen MacArthur Foundation (EMF) (2019). Reuse. Rethinking Packaging. Retrieved from https://www.ellenmacarthurfoundation.org/publications/reuse [Accessed 16 July 2020].

European Commission (EC) (2018). A European Strategy for Plastics in a Circular Economy . Retrieved from https://ec.europa.eu/environment/circular-economy/ pdf/plastics-strategy-brochure.pdf [Accessed 25 May 2020].

Farooque, M. , Zhang, A. , Thürer, M. , Qu, T. , Huisingh, D. , 2019. Circular supply chain management: a definition and structured literature review. J. Clean. Prod. 228, 882–900 .

Fischer, A. , Pascucci, S. , 2017. Institutional incentives in circular economy transition: the case of material use in the Dutch textile industry. J. Clean. Prod. 155, 17–32 . Fletcher, A. , Childon, G.P. , 2014. Using the Delphi method for qualitative, participa- tory action research in health leadership. Int. J. Qual. Methods 13, 1–18 .

Fraccascia, L. , Giannoccaro, I. , Albino, V. , 2019. Business models for industrial sym- biosis: a taxonomy focused on the form of governance. Resour. Conserv. Recycl. 146, 114–126 .

Geissdoerfer, M. , Savaget, P. , Bocken, N.M.P. , Hultink, E.J , 2017. The Circular Economy –a new sustainability paradigm? J. Clean. Prod. 143, 757–768 .

George, V. , Farris, G. , 1999. Performance of alliances: formative stages and changing organizational and environmental influences. R&D Manage. 29 (4), 379–390 .

Geringer, J.M. , 1991. Determinants of partner selection criteria in international joint ventures. J. Int. Bus. Stud. 22 (1), 41–62 .

Geueke, B. , Groh, K. , Muncke, J. , 2018. Food packaging in the circular economy: overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 193, 491–505 .

Geyer, R. , Jambeck, J.R. , Law, K.L. , 2017. Production, use, and fate of all plastics ever made. Sci. Adv. 3 (7), e1700782 .

Goodman, J. , Korsunova, A. , Halme, M. , 2017. Our collaborative future: activities and roles of stakeholders in sustainability-oriented innovation: stakeholder activities and roles in sustainability-oriented innovation. Bus. Strategy Environ. 26 (6), 731–753 .

Guillard, V. , Gaucel, S. , Fornaciari, C. , Angellier-Coussy, H. , Buche, P. , Gontard, N. , 2018. The next generation of sustainable food packaging to preserve our environment in a circular economy context. Front. Nutr. 5, 121 .

Hahladakis, J.N. , Iacovidou, E. , 2018. Closing the loop on plastic packaging materials: what is quality and how does it affect their circularity? Sci. Total Environ. 630, 1394–1400 .

Haas, W. , Krausmann, F. , Wiedenhofer, D. , Heinz, M. , 2015. How circular is the global economy?: an assessment of material flows, waste production, and recycling in the european union and the world in 2005: how circular is the global economy? J. Ind. Ecol. 19 (5), 765–777 .

Hopewell, J. , Dvorak, R. , Kosior, E. , 2009. Plastics recycling: challenges and opportu- nities. Philos. Trans. R. Soc. B: Biol. Sci. 364 (1526), 2115–2126 .

International Organization for Standardization (ISO). (2016). ISO 14021:2016. Environmental labels and declarations –Self-declared environmental claims (Type II environmental labelling). Retrieved from https://www.iso.org/standard/66652. html [Accessed 16July 2020].

Jambeck, J.R. , Geyer, R. , Wilcox, C. , Siegler, T.R. , Perryman, M. , Andrady, A. , Narayan, R. , Law, K.L. , 2015. Plastic waste inputs from land into the ocean. Sci- ence 347, 768–771 .

Kazulyt ˙e, I. , Kruopien ˙e, J. , 2018. Production of packaging from recycled materials: challenges related to hazardous substances. J. Environ. Res. Eng. Manage. 74 (4), 19–30 .

Kelly, M.J. , Schaan, J.-.L. , Joncas, H. , 2002. Managing alliance relationships: key challenges in the early stages of collaboration. R&D Manage. 32 (1), 11–22 .

Kirchherr, J. , Piscicelli, L. , Bour, R. , Kostense-Smit, E. , Muller, J. , Huibrechtse-Trui- jens, A. , Hekkert, M. , 2018. Barriers to the circular economy: evidence from the European Union (EU). Ecol. Econ. 150, 264–272 .

Korhonen, J. , Honkasalo, A. , Seppälä, J. , 2018. Circular economy: the concept and its limitations. Ecol. Econ. 143, 37–46 .

Lahti, T. , Wincent, J. , Parida, V. , 2018. A definition and theoretical review of the circular economy, value creation, and sustainable business models: where are we now and where should research move in the future? Sustainability 10 (8), 2799 .

Leising, E. , Quist, J. , Bocken, N. , 2018. Circular Economy in the building sector: three cases and a collaboration tool. J. Clean. Prod. 176, 976–989 .

Lueneburger, C. , Coleman, D. , 2010. The change leadership sustainability demands. Manage. Rev. 51 (4), 49–55 .

Meherishi, L. , Narayana, S.A. , Ranjani, K.S. , 2019. Sustainable packaging for sup- ply chain management in the circular economy: a review. J. Clean. Prod. 237, 117582 .

Mishra, J.L. , Chiwenga, K.D. , Ali, K. , 2019. Collaboration as an enabler for circular economy: a case study of a developing country. Manage. Decis. .

Okoli, C. , Pawlowski, S.D. , 2004. The Delphi method as a research tool: an example, design considerations and applications. Inf. Manage. 42 (1), 15–29 .

Ordoñez, I. , Rahe, U. , 2013. Collaboration between design and waste management: can it help close the material loop? Resour. Conserv. Recycl. 72, 108–117 .

Pauer, E. , Wohner, B. , Heinrich, V. , Tacker, M. , 2019. Assessing the environmental sustainability of food packaging: an extended life cycle assessment including packaging-related food losses and waste and circularity assessment. Sustainabil- ity 11 (3), 925 .

Pieroni, M.P.P. , McAloone, T.C. , Pigosso, D.C.A. ,2019. Business model innovation for circular economy and sustainability: a review of approaches. J. Clean. Prod. 215, 198–216 .

Reike, D. , Vermeulen, W.J. , Witjes, S. , 2018. The circular economy: new or refur- bished as CE 3.0? Exploring controversies in the conceptualization of the circu- lar economy through a focus on history and resource value retention options. Resour. Conserv. Recycl. 135, 246–264 .

Rhim, J.-.W. , Park, H.-.M. , Ha, C.-.S. , 2013. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 38 (10–11), 1629–2652 .

Rigamonti, L. , Biganzoli, L. , Grosso, M. , 2019. Packaging re-use: a starting point for its quantification. J. Mater. Cycles Waste Manage. 21 (1), 35–43 .

Rohrbeck, R. , Konnertz, L. , Knab, S. , 2013. Collaborative business modelling for sys- temic and sustainability innovations. Int. J. Technol. Manage. 63 (1/2), 4–23 .

Ruggieri, A. , Braccini, A.M. , Poponi, S. , Mosconi, E.M. , 2016. A meta-model of in- ter-organisational cooperation for the transition to a circular economy. Sustain- ability 8, 1153 .

Schmidt Rivera, X.C. , Leadley, C. , Potter, L. , Azapagic, A. , 2019. Aiding the design of innovative and sustainable food packaging: integrating techno-environmen- tal and circular economy criteria. Energy Procedia 161, 190–197 .

Shah, R.H. , Swaminathan, V. ,2008. Factors influencing partner selection in strategic alliances: the moderating role of alliance context. Strategic Manage. J. 29 (5), 471–494 .

Shirley, M.H. , 1981. Working together: Cooperation Or collaboration?. Research and Development Center for Teacher Education, Texas University, Austin R&D-3123 .

Solesvik, M.Z. , Westhead, P. ,2010. Partner selection for strategic alliances: case study insights from the maritime industry. Ind. Manage. Data Syst. 110 (6), 841–860 .

Witjes, S. , Lozano, R. , 2016. Towards a more Circular Economy: proposing a frame- work linking sustainable public procurement and sustainable business models. Resour. Conserv. Recycl. 112, 37–44 .

World Economic Forum (WEF), Ellen MacArthur Foundation (EMF), McKinsey & Company, 2016. The New Plastics Economy —Rethinking the Future of Plastics Retrieved from http://www.ellenmacarthurfoundation.org/publications .